Step 7.1: Gripper Sub-Assembly

warning

Prerequisites

Before starting the assembly, please configure motor IDs by following Step 1: Setup Motor ID.

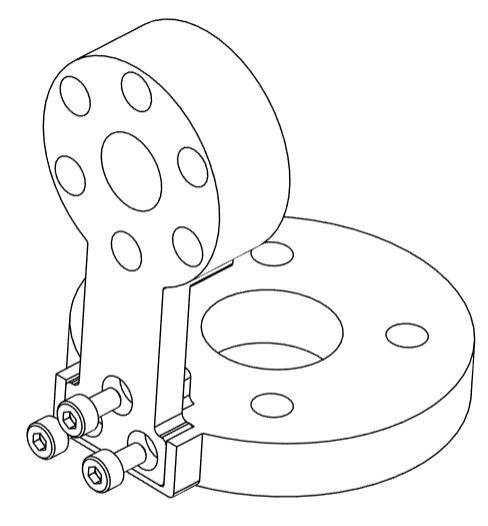

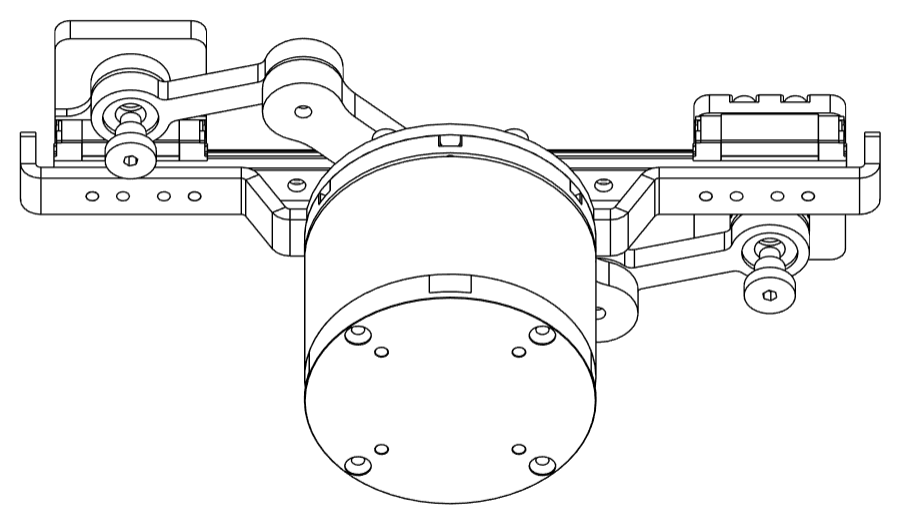

- Attach

J8_AtoJ8_Busing 3M3x6bolts

- Attach

rail_connectorto theJ8motor using 6M3x8bolts. Ensure that the flanges ofrail_connectorare aligned to the two Power+CAN ports ofJ8

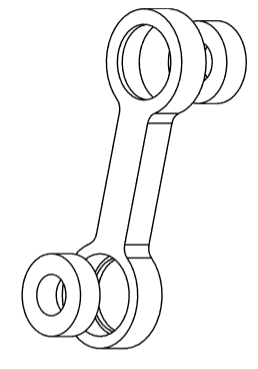

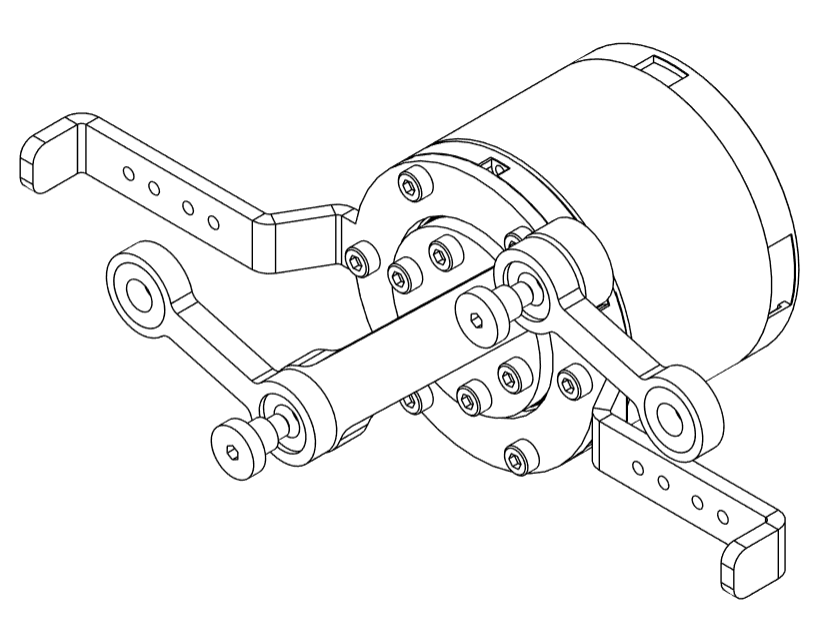

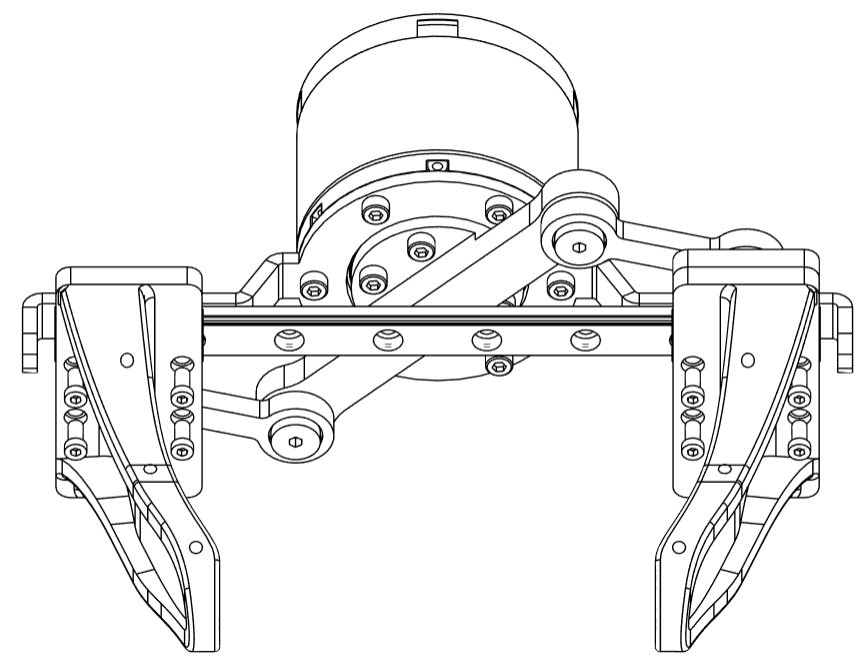

- Carefully insert bearings

MR126ZZintoswivel_link. Note that two bearings need to be inserted from opposite directions.

- Connect

swivel_rotorto the rotor ofJ8using 4M3x8bolts.

- Attach the two

swivel_linkcomponents to theswivel_rotorusing step boltsDBSY4-5-4. Make sure the bearings are oriented such that the fully exposed (open) side of each bearing faces toward theswivel_rotor, as shown in the image. This orientation ensures proper alignment and freedom of movement for the linkages.

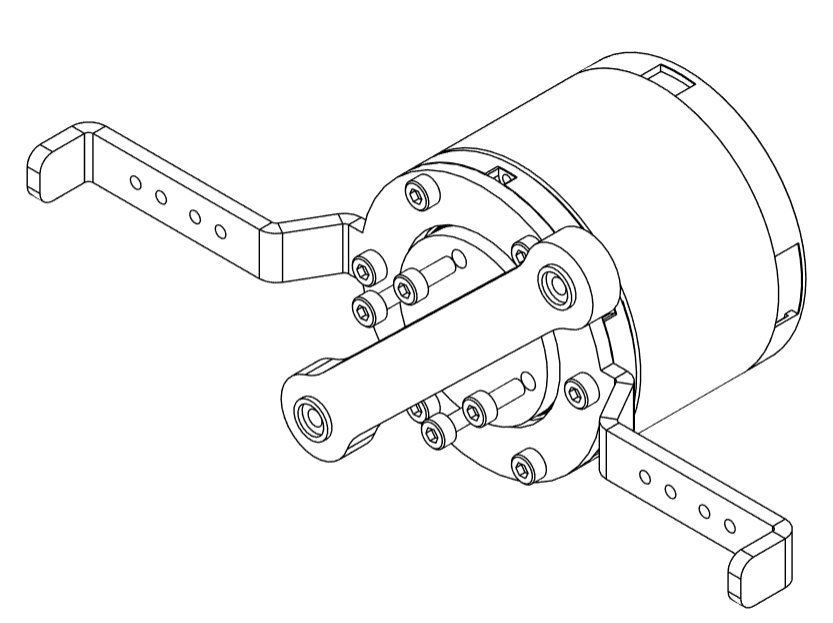

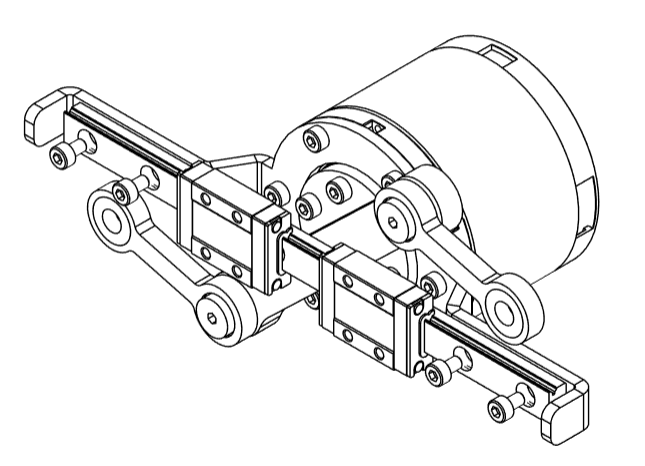

- Attach the linear guide to

rail_connectorusing 4M3x5bolts.

- Secure the

rail_CNC_attachmentto the slider blocks of the linear guide using four low-profile boltsKBBS3-6. Ensure that therail_CNC_attachmentextends in the same direction as theswivel_link. This orientation simplifies the alignment and final assembly steps.

- Connect the two

swivel_linkcomponents to therail_CNC_attachmentusing step boltsDBSY4-5-4.

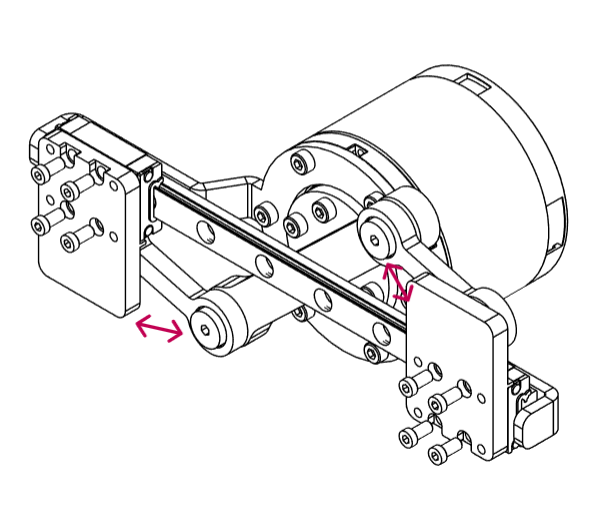

- Attach the jaws to the

rail_CNC_attachmentusing 4 low-profile boltsKBBS3-6. Ensure that the jaws are properly aligned for perfect assembly.

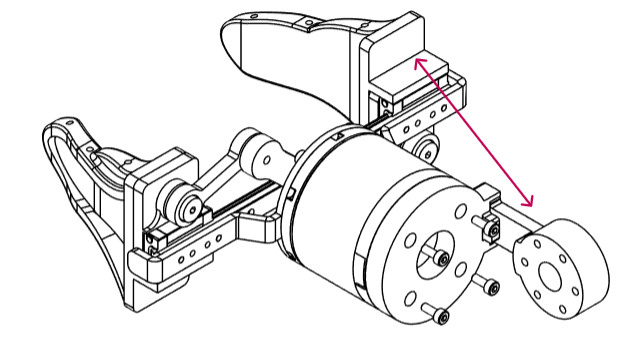

- Mount the subassembly created in Step 1 to the rear face of the

J8motor using fourM3×8bolts.

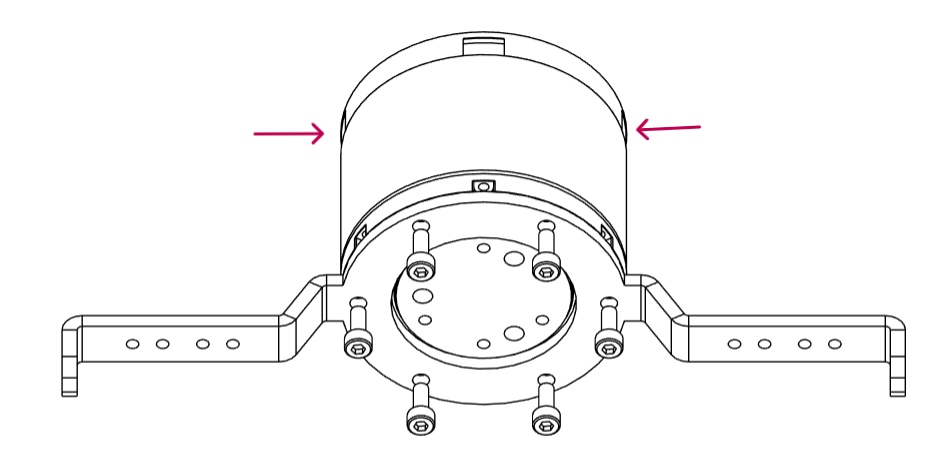

-

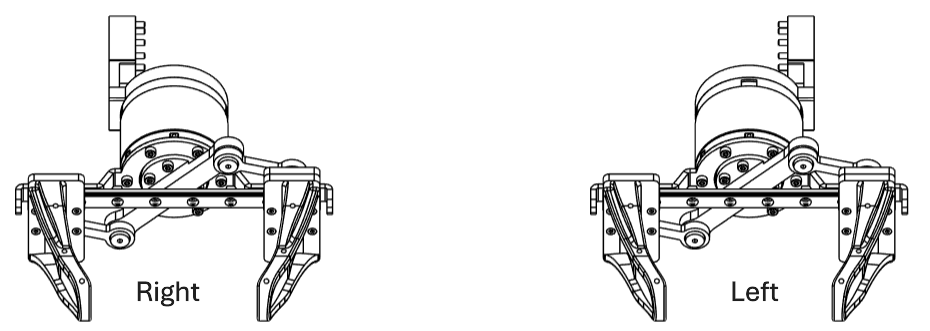

When assembling the right arm, ensure the

J8_Apart is aligned with the right jaw. -

When assembling the left arm, align

J8_Awith the left jaw.

The alignment ensures proper mechanical coupling and correct orientation of the jaws during operation, as indicated by the arrows in the image.

info

This completes the Gripper Sub-Assembly.

info

For the gripper surface, we recommend using the following 3M tape:

https://www.amazon.com/gp/product/B0093CQPW8/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1