Safety Guide

Please read this guide carefully before operating OpenArm and use it safely at your own risk.

We aim to realize a society where robots can be closer to people’s lives and provide meaningful support in daily activities. To achieve this, it is essential to ensure the safety and peace of mind of everyone involved in the development of robots, the environments where robots operate, and the people who interact with them. This guideline outlines key points you should be aware of to use OpenArm safely and responsibly. Please understand that the information presented here is only an example; true safety can only be ensured through sincere risk assessment and continuous improvement of safety measures. We hope you will become a member of the OpenArm community and join us in upholding and expanding this culture of safety.

Safe Use Requirements

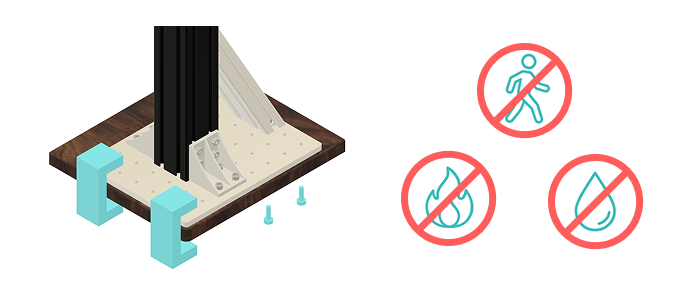

1. Install in a safe location

When installing OpenArm, securely fasten it with screws or clamps to a flat and stable surface. Avoid placing it near fragile objects, flammable materials, or sources of moisture. Additionally, make sure there are no walkways or passages nearby where people frequently pass.

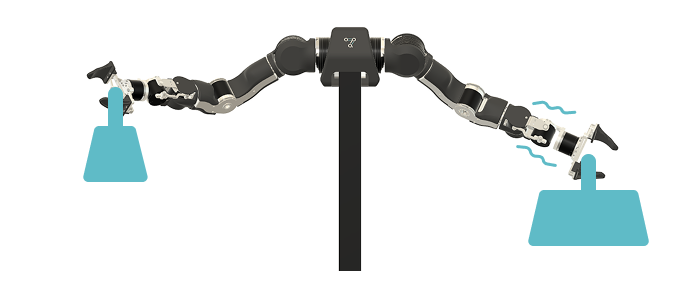

2. Maintain a safe distance

When operating OpenArm, always ensure that no part of your body or any objects enter its range of motion. When approaching the robot for adjustments, always check that the power is turned OFF, and make sure that people nearby do not accidentally turn it ON. If necessary, use barriers or markings to restrict access to the operating area.

The range of motion changes when handling large objects or attaching original end effectors.

When it is unavoidable to approach the OpenArm during teleoperation, keep a safe distance from dangerous areas such as elbows, shoulders, and protruding parts of the end effector, where fingers can easily get caught.

3. Wear appropriate Protective Equipment (PPE)

Always wear safety goggles when operating OpenArm. In addition, wear other protective equipment (PPE) such as safety shoes, helmets, or gloves as needed.

When you need to approach a robot for teleoperation or other purposes, wear clothing that fits your body well to avoid getting caught up in it.

4. Operate within specified limitations

Do not operate OpenArm beyond the specified payload limits for a single arm or both arms. When using an end-effector, also ensure that its payload capacity is not exceeded.

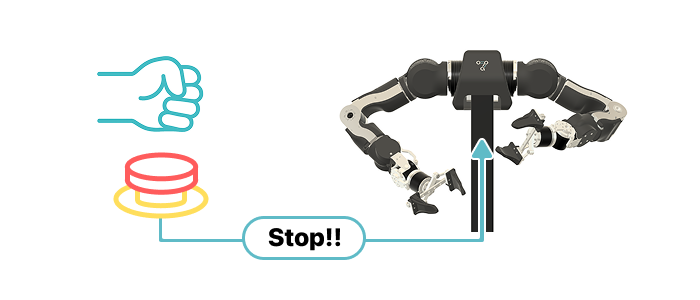

5. Prepare for an emergency stop

Familiarize yourself with the location and operation of the emergency stop device so that you can activate it immediately if something abnormal occurs. The emergency stop switch should be installed in a safe position at a sufficient distance from OpenArm.

OpenArm has high backdrivability suitable for bilateral control. Be aware that if power is lost due to an emergency stop, the load being held will fall rapidly.

6. Assess risks and continuously improve

Record and regularly review any hazards or improvement points you notice during use. Safety must be continuously enhanced through the cooperation of all users — it cannot be ensured only once. By joining the community below, you can take part in discussions about improving safety.

Safe Maintenance and Inspection

To keep OpenArm operating safely, daily inspections and maintenance are essential. Pay particular attention to the following points to detect any abnormalities or wear at an early stage.

Loosening of base fasteners and screws on OpenArm

Repeated movement in certain postures or vibrations can cause screws or clamps to loosen unexpectedly. Loose screws at the base or around the arm’s joints may lead to serious accidents. Always check for any looseness before operating OpenArm.

Damage to mechanical limits

Each joint is equipped with mechanical limits to prevent abnormal postures and protect wiring. These mechanical limits can become deformed or broken by strong impacts. If operation continues with damaged mechanical limits, they may fail to prevent abnormal joint movement in the event of a malfunction. Check the condition of these parts regularly and replace them if necessary.

Unusual noises or catching in joints

Damage caused by excessive loads or impacts during operation can result in unusual noises or catching when moving joints. This is often caused by deformation of the frame or covers, damage to the motor gearbox, or cables getting caught. Identify the location of the noise or catching and investigate the cause thoroughly.

Damage to wiring and connectors

Repeated sharp bending or improper connection and disconnection can damage wiring and connectors. If cables or connectors are damaged, OpenArm may not function correctly, and electrical problems such as damage to the power supply or control devices can occur. If you notice any abnormal operation, immediately turn off the power and check cables from the base to the end for any damage.